Energetic Drinking Water

Development of a Micro-Turbine to Improve the Extraction of Energy from Water Supply Systems

Drinking water is usually not associated with energy production. Nevertheless, currently more than 60 GWh are produced by drinking water networks, which covers the electricity consumption of approximately 12’000 households. With a newly designed micro-turbine, developed by the HES-SO and EPFL with the support of the SCCER-SoE and KTI Duo Turbo project, this amount could be doubled.

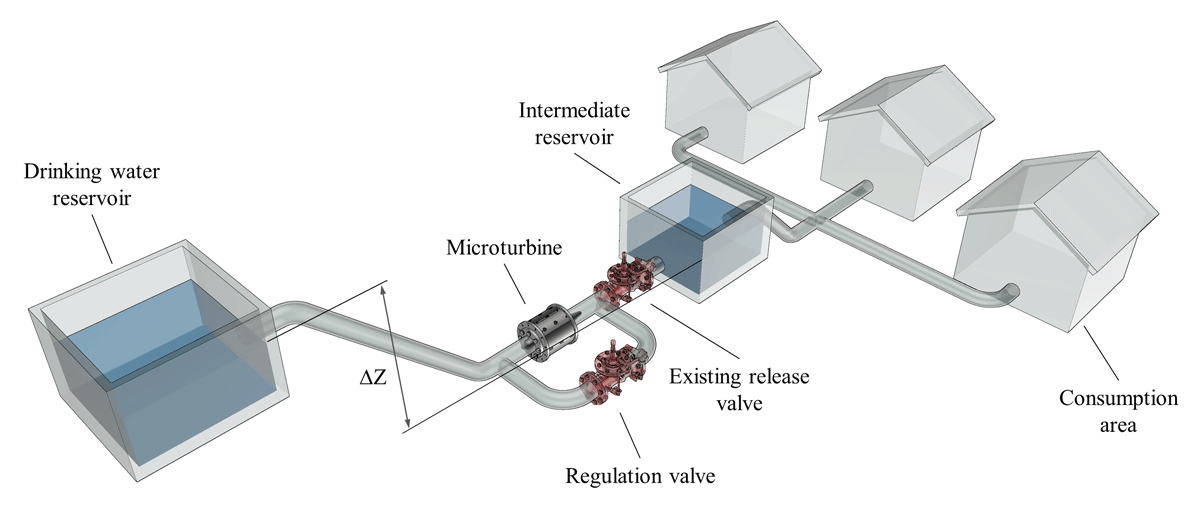

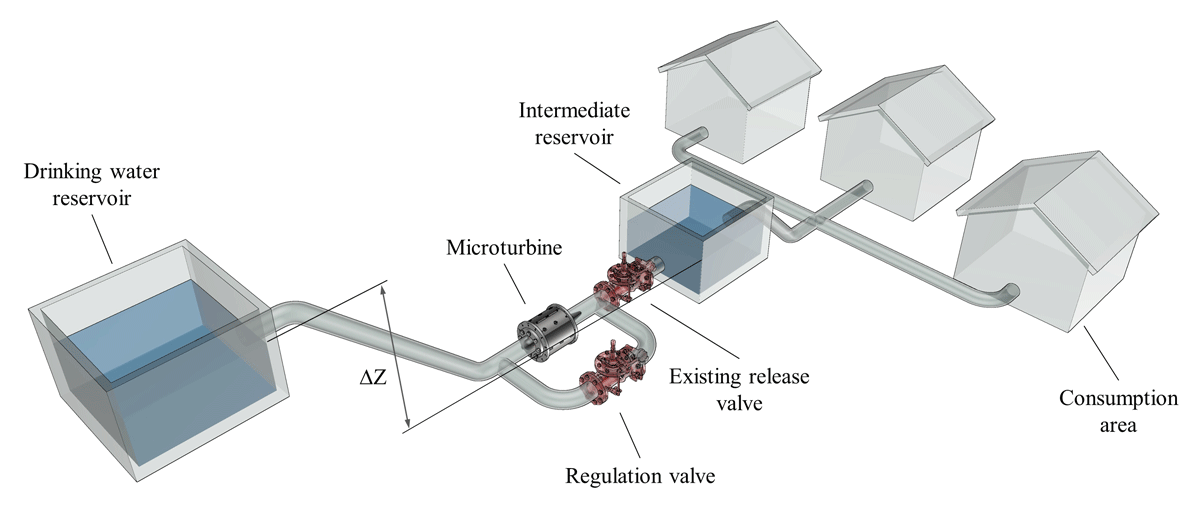

Drinking water systems with a great potential for energy production capture their water in the mountains and deliver it further down in the valley. Small-scale turbines can harvest the exceeding pressure for electricity production. The installed power varies between ten and a few hundred kilowatts. Even though this capacity could be considered as negligible on country scale, it is not the case for a village. In addition, using existing drinking water infrastructure for electricity production is advantageous because it minimizes environmental impacts and installations costs.

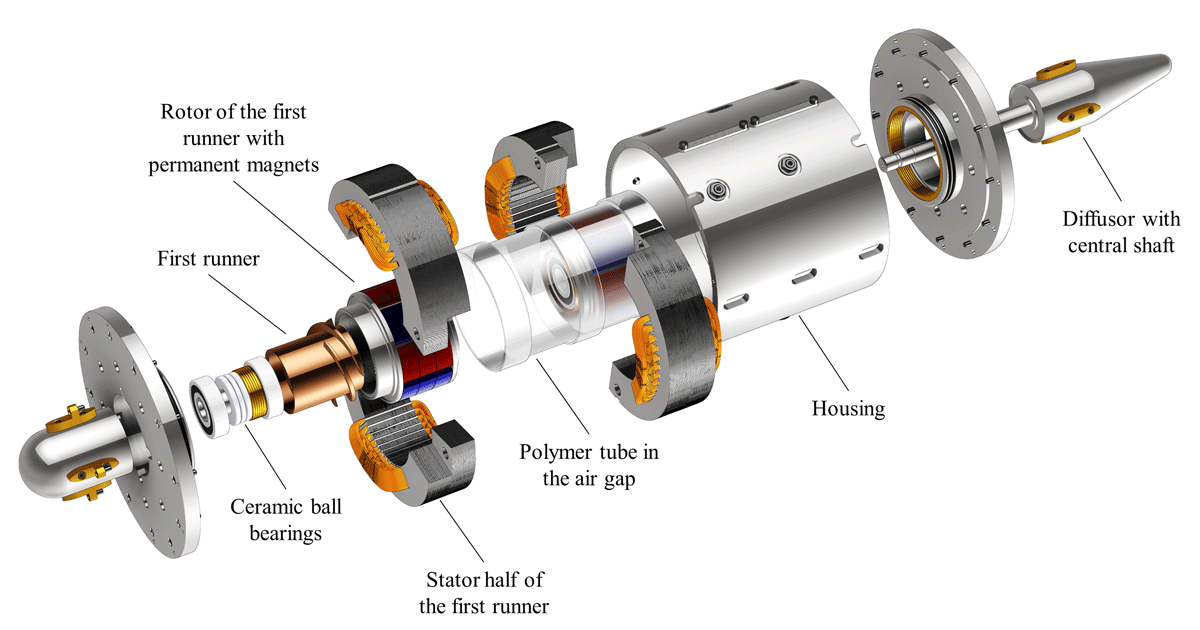

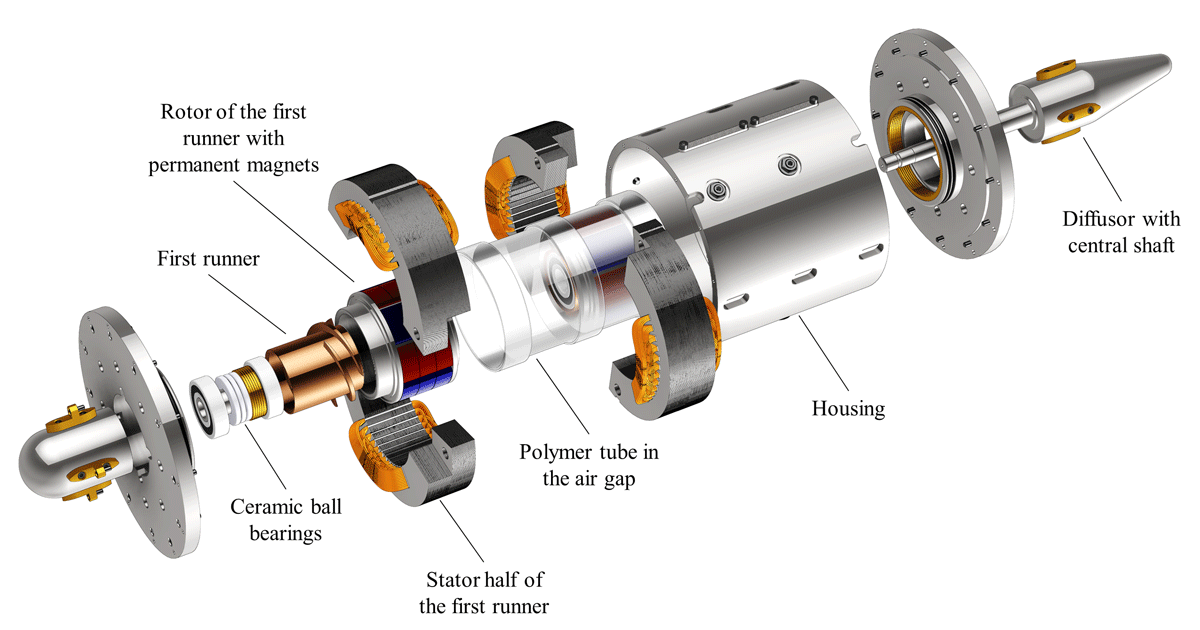

The newly designed micro-turbine helps to increase the productivity of such systems. The axial hydraulic machine ensures a lean manufacturing and installation on water utility networks. It is the core technology for a range of standard energy recovery stations, developed in this project. Innovations lie in the concept of two counter rotating runners, each runner holding its own tailored rim generator. This setting ensures the possibility of stacking several stages in series to add the pressure which can be recovered for a given discharge. A wide range of hydraulic power can be covered from 5 kW to 25 kW to harvest a maximum of energy dissipated in release valves of water supply systems.

A first prototype with one stage and a maximal power of 5 kW has been built and tested at the end of 2015 in the HES-SO hydraulic laboratory for small hydropower. The first product is now under development focusing on the mechanic optimisation to improve the robustness and the efficiency of the machine. After an experimental campaign on the laboratory test rig to confirm this improvement, the turbine will be installed within the second phase of the SCCER-SoE. Several potential sites, already identified, will then be equipped.